Flame Laminator / Bonder Equipment

Elevate Your Production with Flame Lamination Equipment

U.S. Webcon is proud to offer exceptional flame lamination equipment tailored to your production needs.

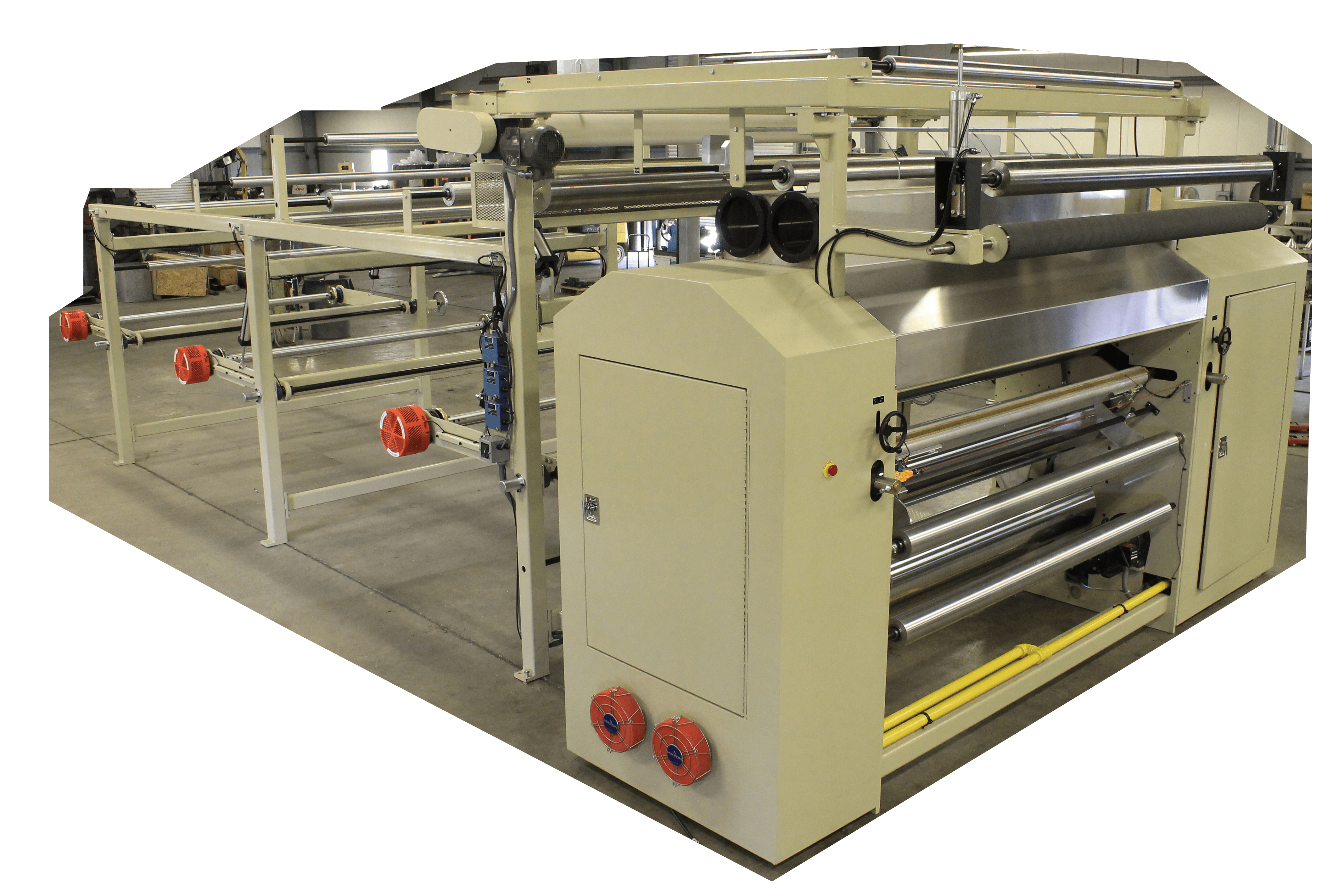

Automotive Flame Laminators

Our automotive flame laminators are a versatile solution designed specifically for long runs or continuous lamination for automotive body cloths and automotive headliners. With customizable options, this machine is tailored to meet your specific requirements.

Commission Flame Laminating Equipment

U.S. Webcon also offers commission flame laminators, a more economical option for short runs and frequent changeovers. This machine is designed for the toll or commission laminating market and provides cost-effective solutions without compromising quality.

Single-Burner Flame Lamination for Two-Ply Bi-Lamination

When it comes to two-ply bi-lamination projects, our single-burner flame laminator is an ideal choice. This machine is designed for laminated products that require a two-ply bi-lamination process. Perfect for proprietary items manufactured by the OEM.

Heavy-Duty Flame/Foam Tri Laminator

When you need to laminate polyethylene foam to foam, trust in our heavy-duty flame or foam tri-laminator. Our equipment is specially crafted for the sports, gymnastics, and wrestling mat industries. This robust and heavy-duty machine ensures efficient lamination of thick webs.

Impulse Sealer/Butt Splicer Equipment

With our heavy-duty foam impulse butt splicer, we offer a seamless solution for splicing. The minor defect created by our splicer is preferable to the significant defect left by the tape. A single continuous splice is achieved by placing the ends of the webs between heated and cold-forming platens.

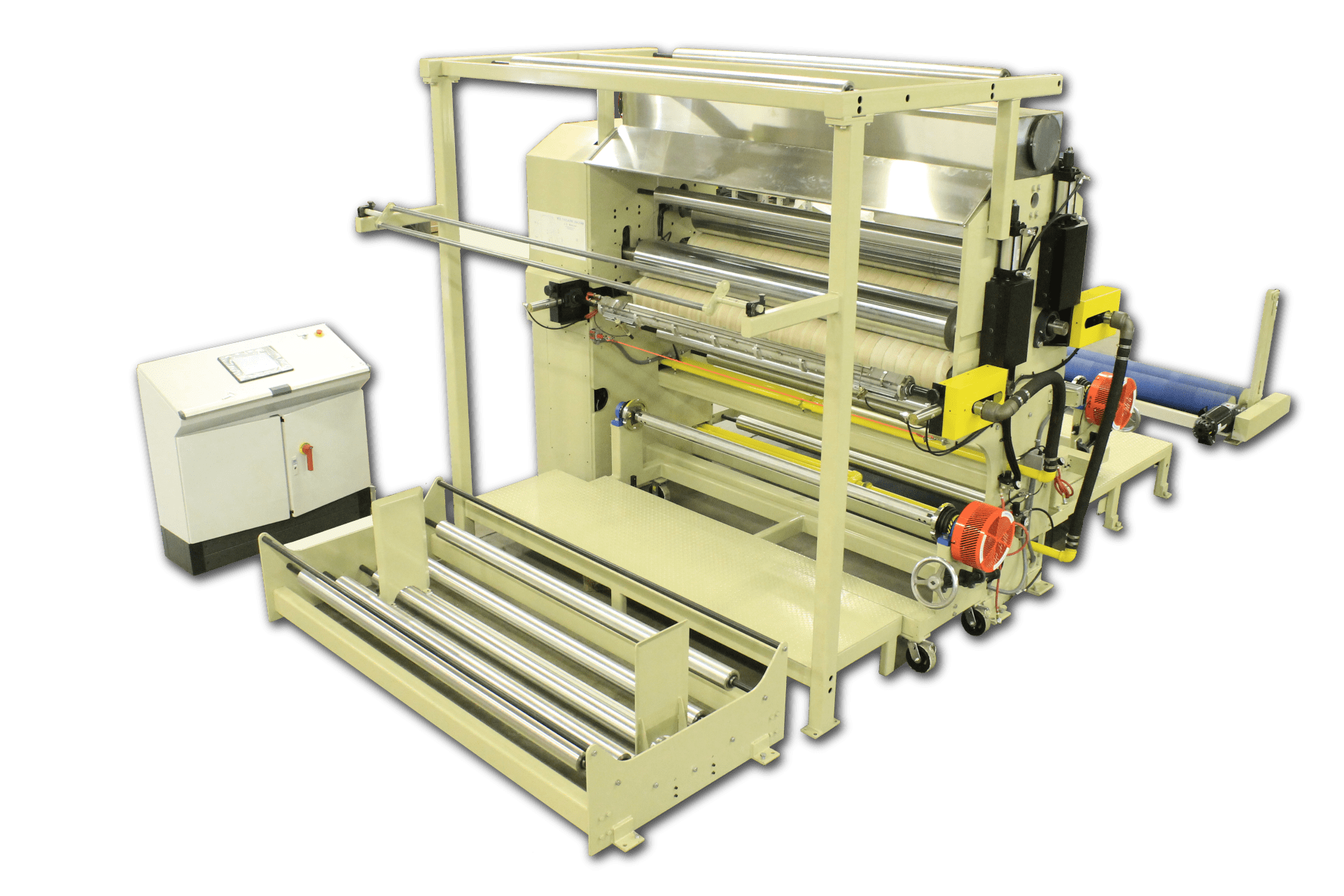

Four-Roll Flame Laminator

Our four-roll flame laminators are the perfect fit for laminated products requiring three-ply try-lamination. This machine offers superior laminating capabilities through two independent two-roll nips.

Connect with Us

At U.S. Webcon, we understand that your unique needs may require modifications to our designs. Our team of experienced engineers is ready to discuss your specific application requirements. Contact us today at (570) 644-1401 to learn how we can help you achieve optimal results.

What is a flame laminator?

A flame laminator is a machine that uses an open flame to melt a foam polymer surface and using the hot viscous surface to bond with another material without adhesives.

What materials can be laminated with flame lamination equipment?

Common materials include polyurethane (PU) foam, polyethylene (PE) foam, textiles, non-wovens, plastic films, and synthetic leather.

Is flame lamination safe?

Yes, when proper safety measures are in place, such as ventilation, flame control, and fire suppression systems.

What are the advantages of flame lamination over adhesive lamination?

-

No additional adhesives needed

-

Strong, durable bond

-

Cost-effective for large-scale production

-

Environmentally friendly (reduces the need for chemical adhesives)

-

What industries use flame laminations?

-

Automotive (seat cushions, interior panels)

-

Furniture (foam bonding for upholstery)

-

Packaging (protective foam layers)

-

Medical (laminated fabric materials)

-

What are the energy requirements for a flame laminator?

It depends on the burner type, material thickness, and processing speed, but gas burners (natural gas or propane) are commonly used.