Inline Inspection Winders

and Rewinders

Top-Quality Inspection Winders

At U.S. Webcon, we understand the critical importance of visual inspection in production. Our company offers inspection winders designed to unwind and rewind narrow woven fiberglass webs for manual visual web inspection. With our state-of-the-art machinery and customizable options, you can achieve unparalleled precision and detect even the slightest defects.

Surface-Driven Unwind Stand

Our inspection winders are specifically designed to inspect the web surface of paper, film, and nonwoven products on a roll-to-roll basis. Our winders use either backlighting or optional top lighting to highlight web defects for visual detection by the operator, ensuring exceptional quality control.

Featuring a surface-driven unwind stand, our inspection winders ensure seamless web unwinding for precise inspection. This design ensures smooth and consistent tension throughout the unwinding process, minimizing the risk of damage or deformation to the web.

Our equipment also features a surface-driven unwind stand, ensuring seamless unwinding of the web for precise inspection. With a sloped backlit inspection table, you can easily detect any defects or abnormalities on the web surface. Our center-driven rewind stand, equipped with dancer tension control and guidance, ensures optimal rewinding of the inspected web.

Customized Options for Enhanced Inspection

U.S. Webcon offers a range of options to enhance your inspection process. Choose between top or overhead lighting to illuminate the web surface. Opt for edge trimming for improved aesthetics and functionality. Enjoy the benefits of automatic edge guiding or manual positioning for precise alignment.

Consider closed-loop load cell tension control for consistent tension throughout the inspection process. Additional options include two drum surface winders, center unwinds, splice boards and clamps, and vacuum hold-down to replace clamps.

Accurate Footage Counts for Seamless Production

With our AC drives featuring dynamic braking and two preset counters, you can achieve accurate footage counts during inspection. These counters signal the drive to start de-accelerating before stopping, ensuring precise measurement and facilitating seamless production.

Trust U.S. Webcon to meet your web inspection needs. Elevate your visual inspection process and ensure the highest quality standards for your products. Reach out to us today to discuss your specific needs.

Inspection Winders / Rewinders

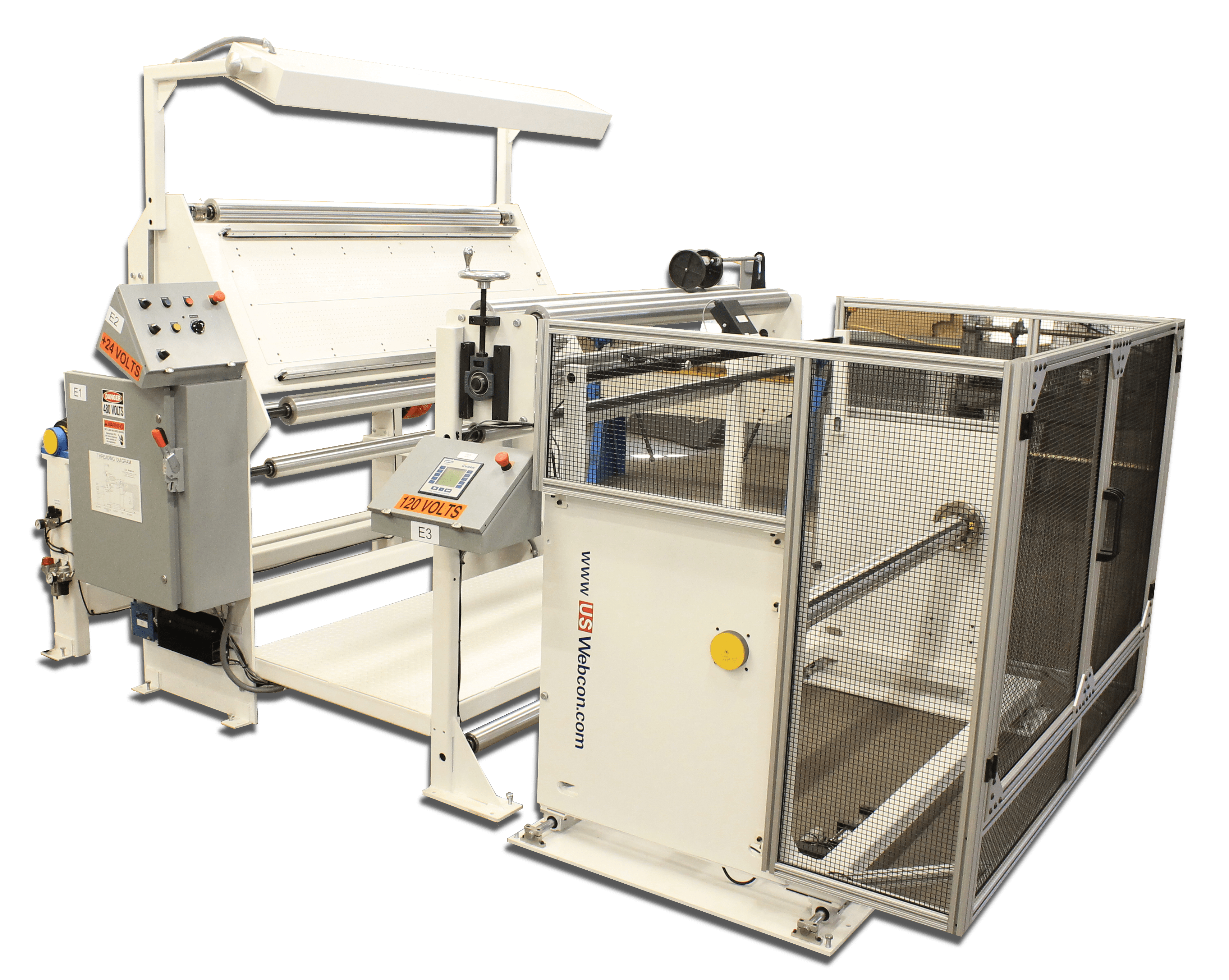

This Inspection Winder is used to unwind and rewind a TPO automotive product web for manual visual web inspection.

Machinery Included:

- Center Unwind Stand

- Sloped Toplit inspection table

- Center-driven rewind stand with load tension control and guiding

US Webcon offers a series of wide web Inspection Winders to meet your production needs with numerous features and customized options to fit your specific requirements. The US Webcon inspection winder is designed to inspect the web surface of paper, film, and nonwoven products on a roll-to-roll basis using backlighting or optional top lighting to highlight web defects for visual detection by the operator.

Options:

- Top or overhead lighting

- Edge trimming

- Automatic edge guiding or manual positioning

- Closed loop load cell tension control

- Two drum surface winders

- Center unwinds

- Splice boards and clamps

- Vacuum hold down to replace clamps

- Accurate footage counts using AC drives with dynamic braking coupled with two preset counters that signal the drive to start de-accelerating before stopping

Cantilevered Inspection Winders

At U.S. Webcon, we understand the application of your Web Handling Processes. We can modify the above design to meet your specific needs and requirements. Call us to discuss your application with one of our engineers at (570) 644-1401.

What is an inspection winder and rewinder?

An inspection winder is a machine used to wind materials such as films, papers, or textiles while simultaneously inspecting the quality of the material. These systems are often equipped with cameras, sensors, or other inspection tools to detect defects like wrinkles, tears, or inconsistencies in the material during the winding process.

What types of defects can inspection winders detect?

-

Inspection winders can detect a variety of defects, including:

- Wrinkles or creases

- Tears or holes

- Foreign materials or contamination

- Print defects (for printed materials)

- Web misalignment

- Color inconsistencies or fading

-

What are some features to look for in an inspection winder?

Key features to look for include:

-

Viewing Area: A large table to view the web surface with back lighting and top lighting.

-

Tension Control: To maintain the correct tension during winding, preventing defects.

-

Automatic Roll Changeover: To ensure continuous operation if needed.

-

User-Friendly Interface: For easy operation and adjustment of inspection settings.

-

Speed Control: To match the winding speed with the material’s sensitivity.

-

Can inspection winders be customized?

Yes, many inspection winders can be customized to meet specific application needs. Customizations can include integration with existing equipment, specialized defect detection systems (e.g., camera or laser-based inspection), or modifications to accommodate different material types and sizes.