Narrow Web Handling

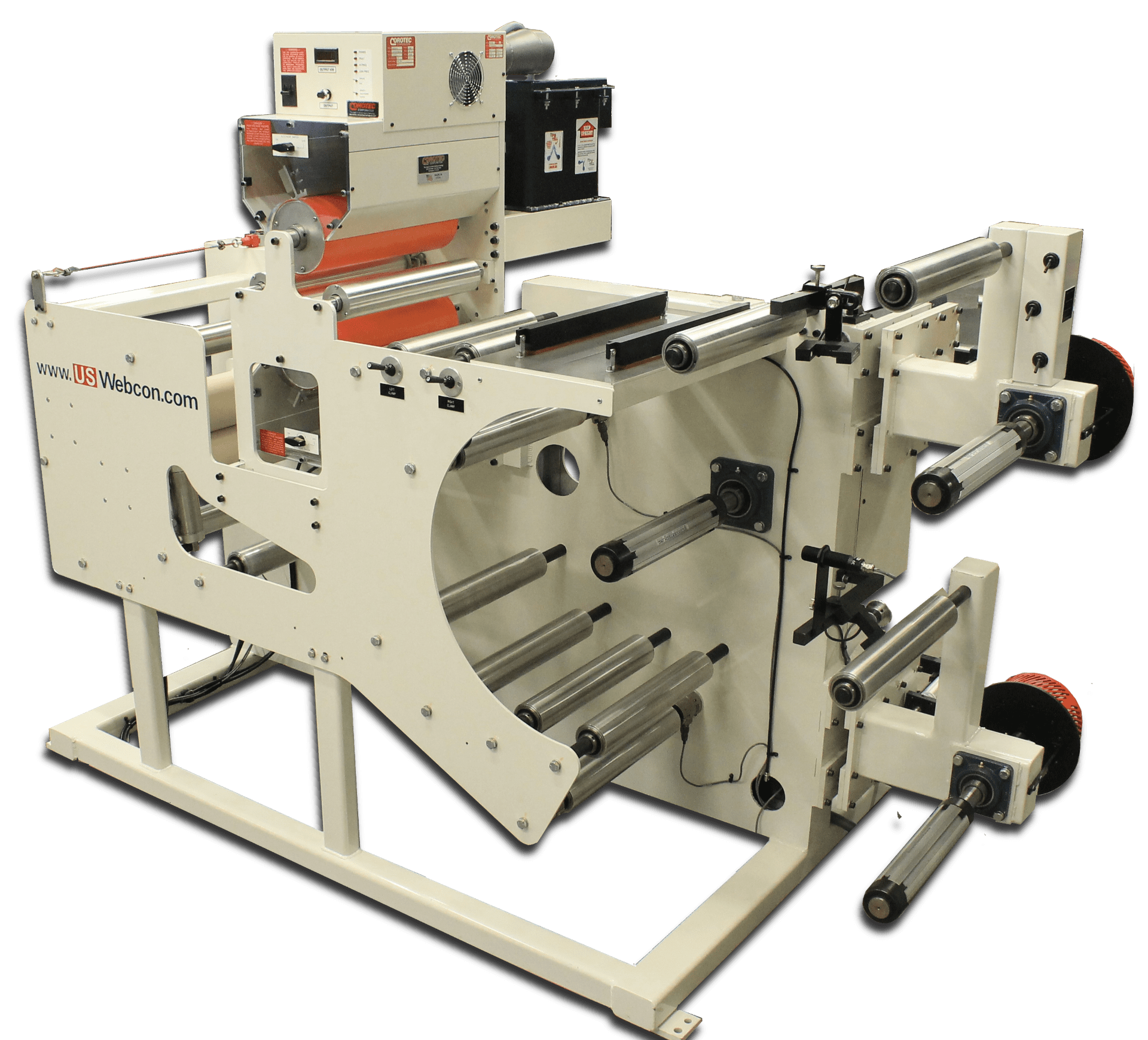

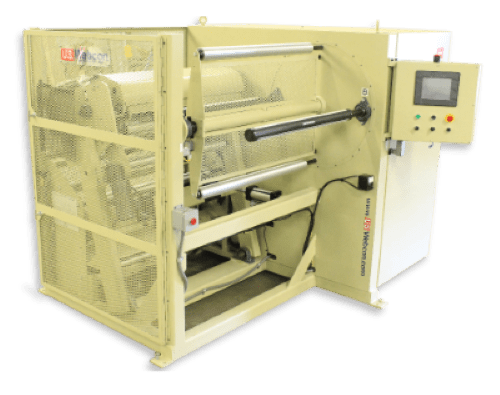

Narrow Web Cantilevered Cold Nip PSA Laminator.

Experience Efficient Production with Narrow Web-Handling Solutions

Our narrow web-handling solutions are designed to optimize your production process. With various features and customizable options, we ensure our stands perfectly align with your requirements. Designed for webs less than 30″ wide, these unwind and rewind stands can be easily configured to accommodate narrow webs, giving you the flexibility you need.

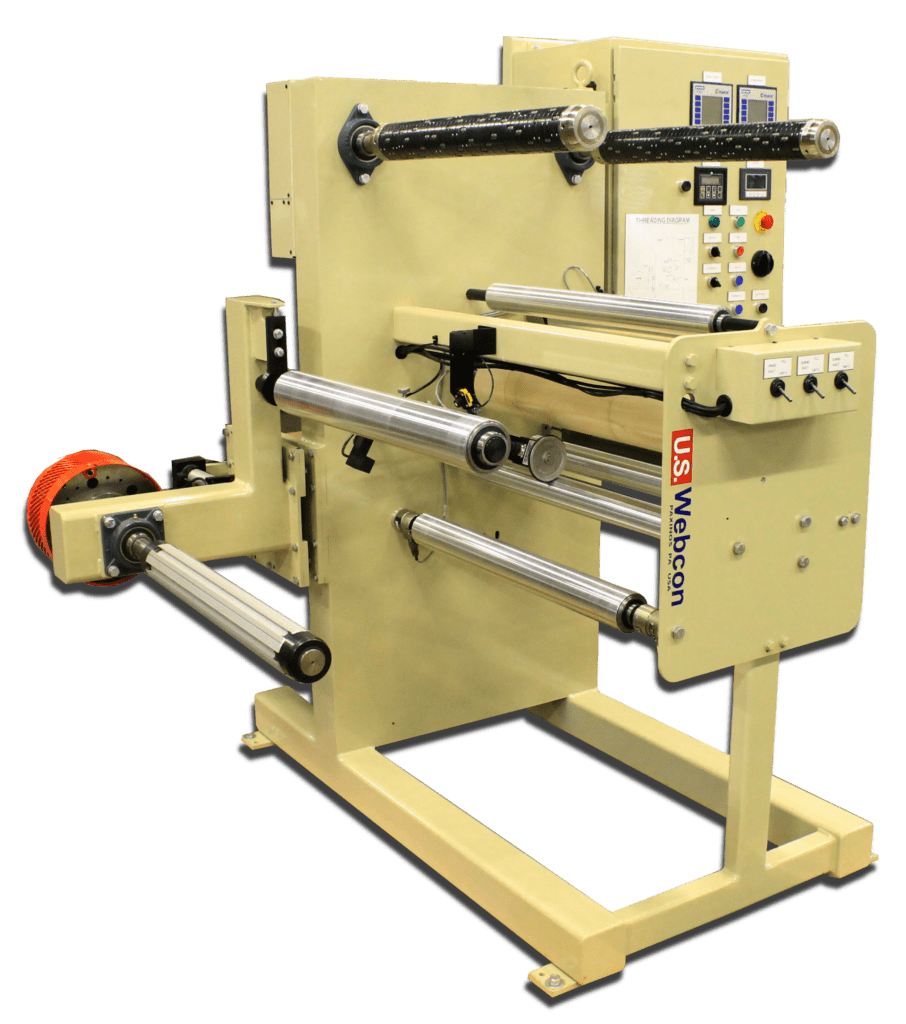

Narrow Web Winding and Unwinding Equipment

- We offer single-position and two-position cantilevered winders and two-position cantilevered unwind stands.

- These winding equipment solutions provide the reliability and precision you demand for your narrow web applications.

Narrow Web Salvage/Inspection Winding System

- This versatile machine serve as both a salvage winder and a web inspection platform. It can effectively correct web defects and provide comprehensive inspection capabilities.

- Experience our equipment’s exceptional functionality for enhanced quality control and productivity.

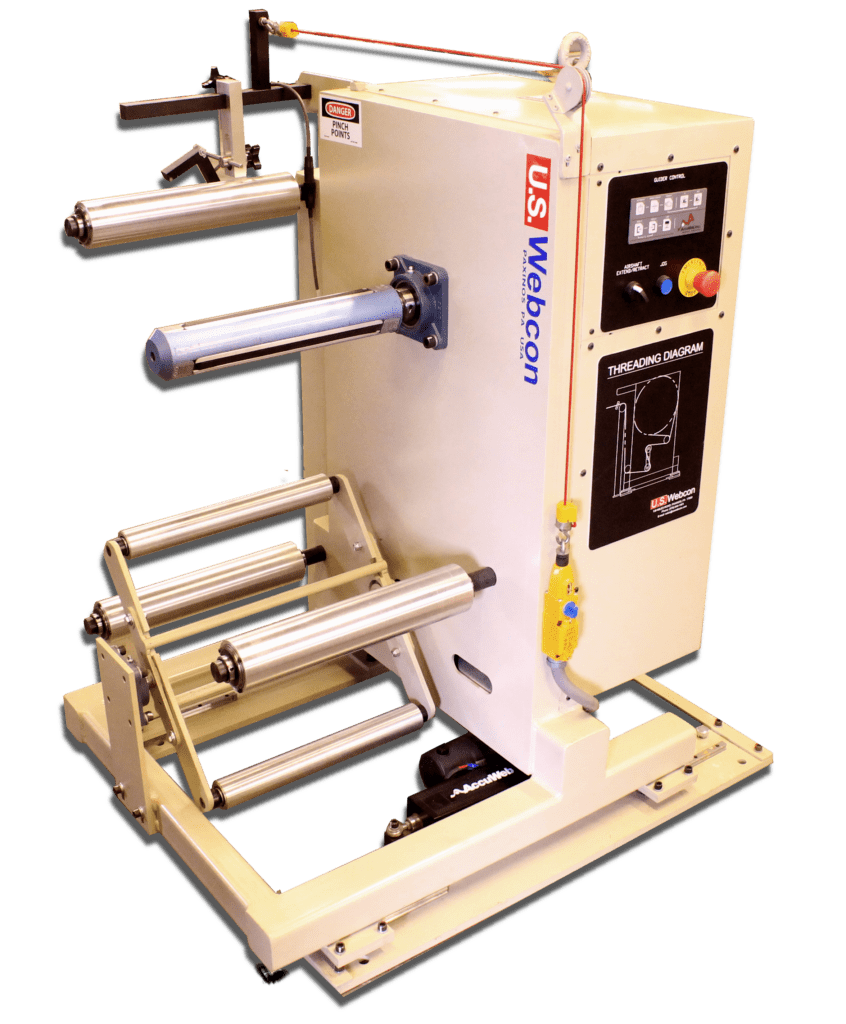

Enhance Efficiency with the Narrow Web Festoon Accumulator

- Complementing our winding equipment, the narrow web festoon accumulator seamlessly facilitates continuous roll-to-roll unwinding and rewinding of your product web.

- Compatibility with our winding equipment ensures uninterrupted production and enhanced productivity.

Narrow Web Cantilevered Duplex Slitter WInder

We complete narrow web handling line to perform most any function that you may require with a comprehensive solution.

- Narrow web cantilvered duplex Slitter Winder

- Has optional closed loop load cell tension control

- Edge or center guiding to locate the web where needed.

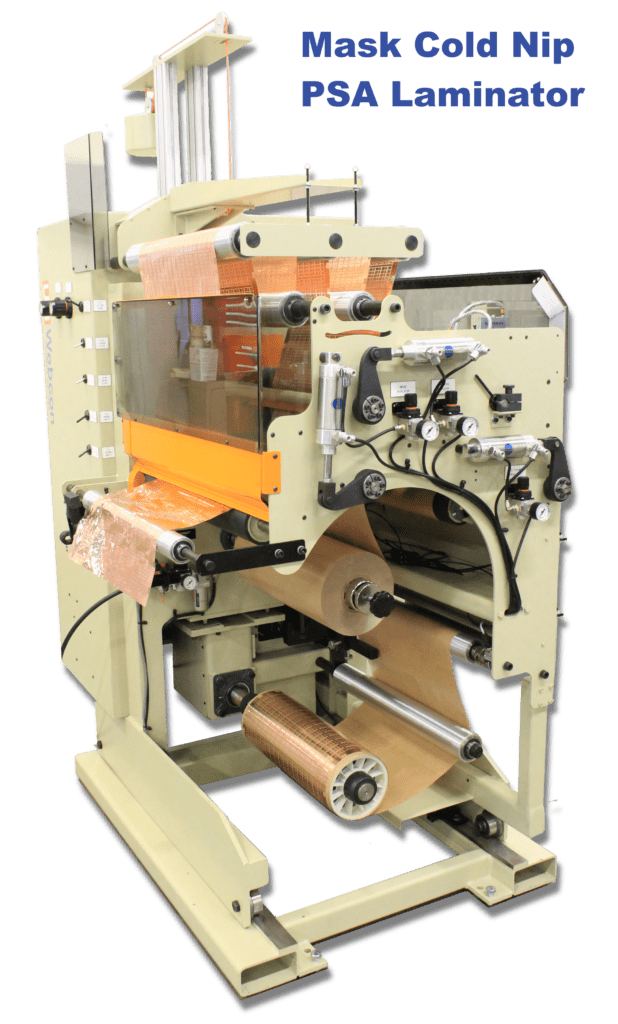

Cold Nip PSA Laminators

- US Webcon offers high quality cold nip psa laminator with integral unwind and rewinds.

- With options for closed loop tension control and edge guiding .

- Optional Corona treaters to treat web surfaces for printing.

Narrow Web Cantilevered Turret Winders

- U.S. Webcon offers high-quality narrow web turret winders designed for the automatic continuous center winding of paper.

- Our cantilevered shafted turret rewind stand delivers exceptional performance with the incorporation of a festoon accumulator.

Unrivaled Flexibility with the Narrow Web Modular Winding System

- Our complete narrow web handling line offers unparalleled flexibility.

- From single-position cantilevered unwinds to splice tables, web festoon accumulators, pull rolls, and turret rewinds, we provide an integrated solution that streamlines your entire production process.

Seamless Transition with Splice Boards and Tables

- Our premium quality splice boards and tables are designed to ensure smooth and precise splicing. These accessories further enhance the productivity and efficiency of your narrow web-handling operations.

- Our comprehensive and innovative solutions provide the efficiency, quality control, and flexibility you need to excel in your industry. Contact us today to explore our exceptional narrow web-handling product line.

What is narrow web handling?

Narrow web handling refers to the process of managing and processing web materials (like films, labels, and flexible substrates) that are typically less than 30 inches wide. It involves unwinding, guiding, tension control, slitting, and rewinding narrow web materials during the printing or converting process.

What challenges are typically encountered in narrow web handling?

-

Tension fluctuations: Inconsistent tension control can cause wrinkles or breaks.

-

Web tracking and alignment: Keeping the web properly aligned is crucial to prevent misregistration and waste.

-

Material stretch: Certain materials, especially films, may stretch unevenly, leading to problems in printing or lamination.

-

Roll handling: The smaller diameter rolls used in narrow web processes can be tricky to manage, requiring specialized unwind and rewind systems.

-

How do you choose the right narrow web handling system?

Key considerations include:

-

Material type and thickness: Ensure the system can handle the specific material you’re working with.

-

Printing/processing speed: The system should meet your production speed requirements.

-

Automation features: Automation can help improve efficiency and reduce operator involvement, reducing the chance of errors.

-

Flexibility: The ability to handle different types of jobs, including short runs, is important.

-

Why is tension control important in narrow web handling?

Proper tension control ensures that the web material is consistently maintained at the right tension throughout the process. If the tension is too high or too low, it can lead to issues like web breaks, wrinkling, or misalignment, all of which impact the quality of the finished product.