Splice Boards and Tables

Upgrade your splicing operations with U.S. Webcon’s manual splice boards and automatic splicing equipment. Our range of features and options ensures seamless splicing of your web substrates.

- Manually actuated splice Clamps.

- Vacuum clamping us a vacuum generator.

- Walkover and lift plate access to web.

- Both top lighting and back lighting available for web inspection.

- Optional 90 Deg. and other cut angles.

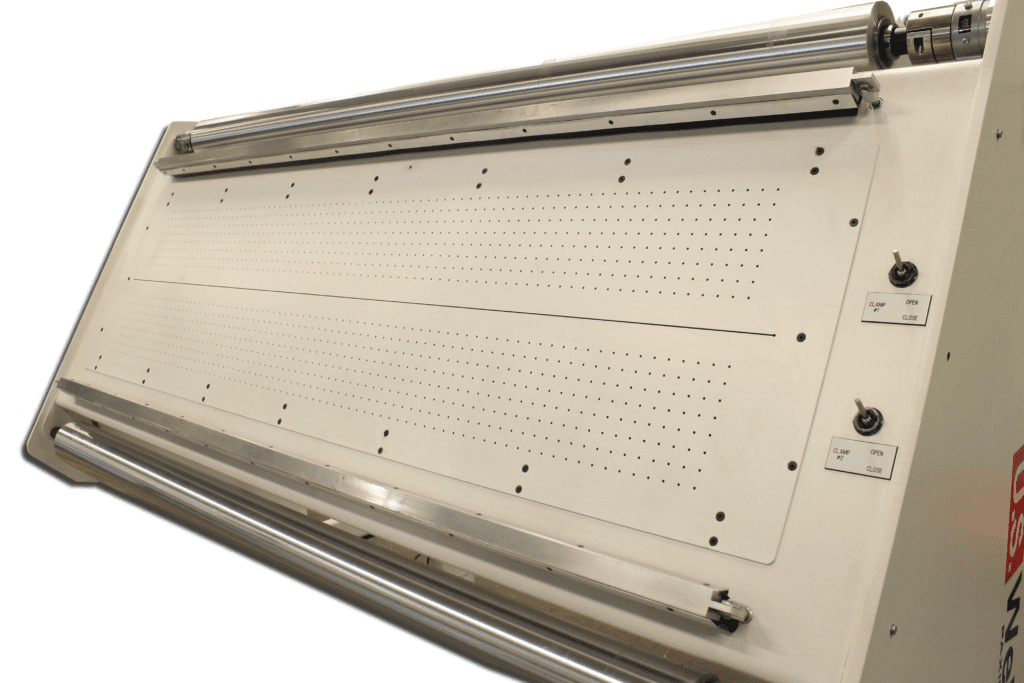

Free Standing Manual Splice Boards and Tables

Foot Mounted Manual Splice Boards with Manual Clamps and Vacuum Clamping

Upgrade your splicing operations with U.S. Webcon’s manual splice boards and automatic splicing equipment. Our range of features and options ensures seamless splicing of your web substrates.

- Custom foot mounted designs.

- Manually actuated splice Clamps.

- Vacuum clamping using a vacuum generator.

- Optional 90 Deg. and other cut angles.

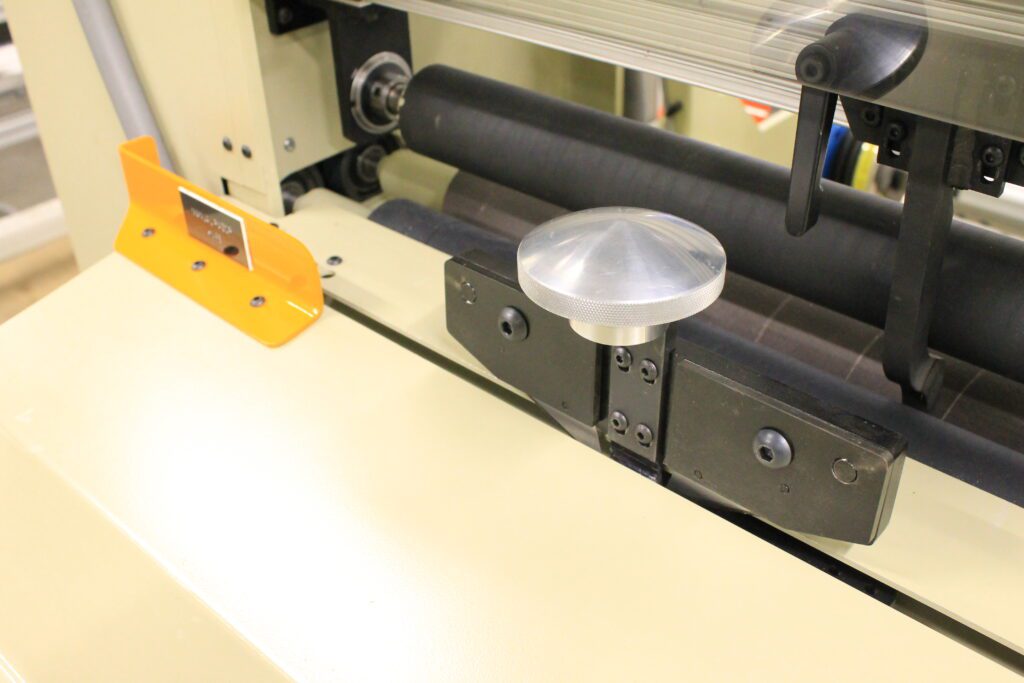

Machine and Custom Foot Mounted Manual Bi-Directional Razor Knife Cut Off

Upgrade your splicing operations with U.S. Webcon’s manual razor cut off knife. Our range of features and options ensures seamless splicing of your web substrates.

- Custom foot mounted designs.

- Manually actuated dual razor knife for operations in both directions.

- Pnuematic or motor driven knife operation available.

- Rotary knife operation also available.

Manual Web Splice Boards

Our splice boards are designed to make butt splices on unwind and rewind equipment with maximum efficiency and accuracy. Their pneumatically actuated clamps securely hold the web substrates while a handheld razor knife is drawn across the blade guide, cutting the new web and the web from the expired roll. The newly spliced web is held together with a piece of tape.

The spice boards can be placed on our equipment or as a standalone mounted on a freestanding framework. We offer various customizable options to tailor our splice boards and automatic splicing equipment to fit your specific production requirements, including:

- Vacuum table hold down for secure web holding.

- Solenoid valve operation using selector switches for smooth operation.

- Pneumatic-operated cross-cut for accurate web cutting.

Automatic Splicing Equipment

Our automatic splicing equipment is designed to save time and provide reliable performance in your production operations. This equipment works by splicing two rolls of web substrate together without stopping the machine. The roll change is made automatically, increasing your productivity and reducing downtime.

Experience Uninterrupted Production

Enjoy uninterrupted production with U.S. Webcon’s splice boards and automatic splicing equipment. Get in touch with us today to discuss your needs.

What is a manual splice table?

A manual splice table is a workstation used in web processing to join the end of an expiring roll to a new roll to form a butt splice. It provides a flat, stable surface for making precise splices using tape, adhesive, or heat-sealing methods.

What are the different types of splicing methods?

-

Overlap Splice – One web overlaps the other and is joined with adhesive or tape.

-

Butt Splice – The two web ends meet edge-to-edge and are held with tape or heat sealing.

-

Heat-Activated Splice – Uses thermal adhesives or ultrasonic welding.

-

How is a web held in place during splicing?

Most manual splice tables use:

-

Clamps (manual or pneumatic)

-

Edge guides for alignment

-

Vacuum hold-down (in some cases)

-

How do I ensure an accurate splice?

-

Use alignment guides or printed registration marks.

-

Apply consistent pressure when securing the web.

-

Use a sharp cutting tool for clean web edges.

-

Ensure proper tension before restarting the machin

-

Can a manual splice table be integrated with other equipment?

Yes, manual splice tables can be positioned near unwind stands, tension control systems, and web guiding systems for seamless roll changeovers.