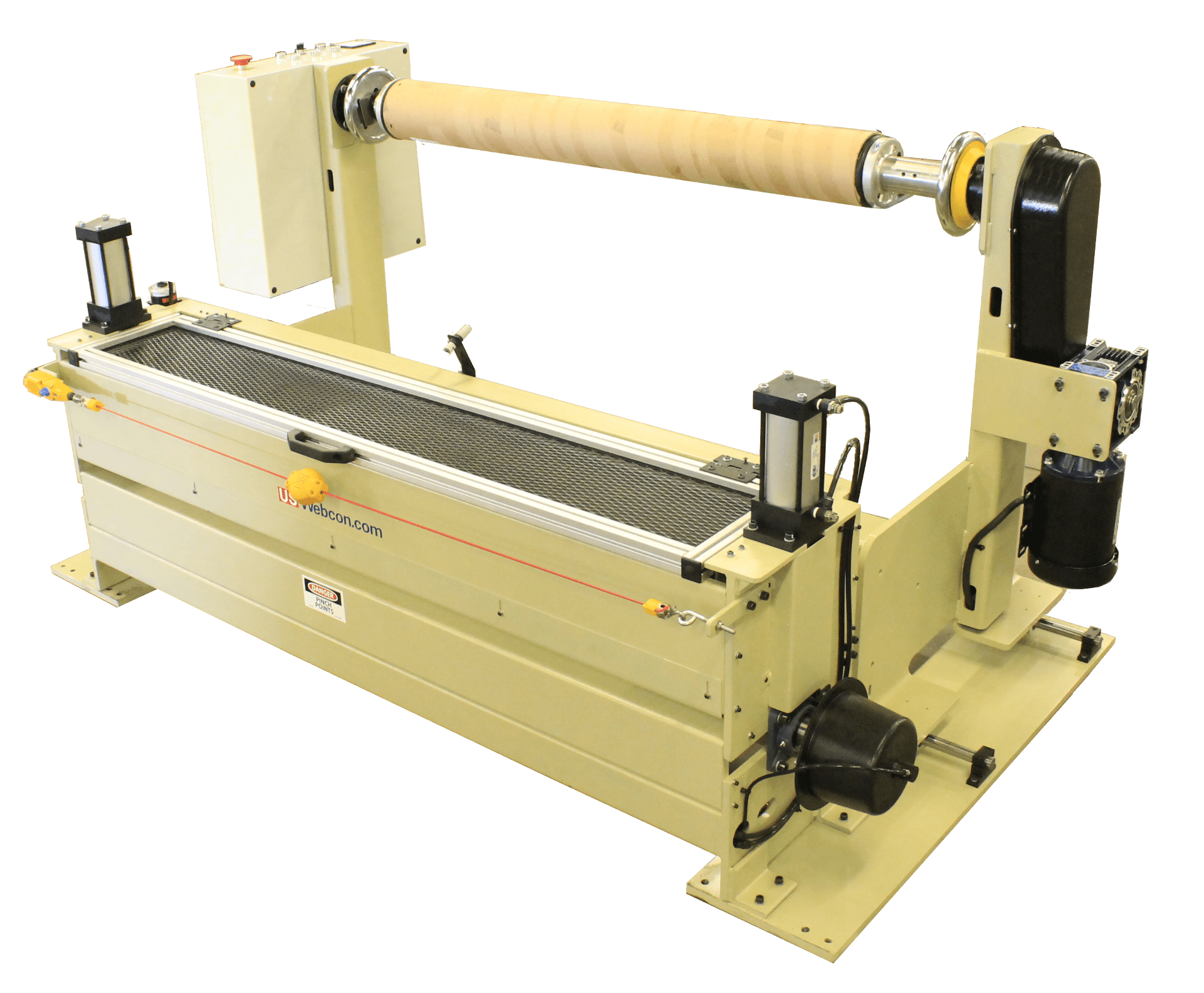

Web Winding Equipment

Explore Our High-Quality Winding Equipment

U.S. Webcon has been providing top-quality, reliable, and innovative equipment to customers worldwide for over three decades. We take pride in our broad range of products catering to the unique needs of several industries.

Our web winding equipment includes shafted center roll winder and shaftless unwinds and rewinds, turret unwinds and winders, automatic surface winders, inspection winders, surface-driven textile winders and rewinds, small roll log winders, narrow web handling equipment, cradle let-off stands, splice stations, and web folding equipment. Our equipment also features advanced technology and is available in customized designs to fit our customers’ application specifications.

Experience the U.S. Webcon Advantage

At U.S. Webcon, we provide tailored equipment that meets the unique needs of our customers. We work hard to provide top-quality, reliable, and durable equipment that fits seamlessly into your production environment.

Get in Touch

Contact us to learn more about our products and how we can help you improve your productivity.

What is Web Winding Equipment?

Web winding equipment refers to machinery used in industrial processes to handle and manipulate “webs” of flexible materials. A “web” in this context is a continuous sheet of material, such as:These materials are often supplied in large rolls and need to be unwound, processed, and then rewound into smaller, more manageable rolls.

What are the critical functions used in the web winding machinery process?

- Unwinding: – This involves smoothly feeding the web material from a large roll into the processing line.

- Winding (Rewinding): – This is the process of rolling the processed web material onto cores to create finished rolls.

- Tension Control: – A critical aspect of web winding is maintaining consistent tension on the web to prevent tearing, stretching, or wrinkling.

- Edge Guiding: –This ensures that the web remains aligned as it moves through the process.

- Slitting: – Often, the web needs to be cut into narrower strips, and web winding equipment can integrate slitting capabilities.

What industries use web winding equipment?

Web winding equipment is essential in a diverse range of industries that handle continuous, flexible materials. Here’s a breakdown:

- Printing and Packaging: – This sector uses web winding for handling paper, plastic films, and foils in printing presses, packaging lines, and labeling processes.

- Textile Manufacturing: – Web winding is crucial for processing fabrics, non-woven materials, and other textiles in various stages of production.

- Paper and Film Production: – Industries involved in producing paper, plastic films, and foils rely heavily on web winding for both manufacturing and converting processes.

- Converting Industries: – This broad category includes companies that transform raw web materials into finished products. Applications include slitting, laminating, coating, and other web-based processes.

- Automotive and Aerospace: – These industries utilize web winding for processing materials used in interior components, protective films, and composite materials.

- Medical and Pharmaceutical: – Web winding plays a role in producing medical dressings, bandages, pharmaceutical packaging, and other related products.

- Electronics: – The production of things like flexible circuits, and other electronic components uses web winding equipment.

- Energy: – The production of solar films, and battery components also uses web winding equipment.

Essentially, any industry that works with continuous rolls of flexible materials will likely utilize web winding equipment in some form.

What types of web winding equipment are used in industry?

-

Center winders

-

Surface winders

-

Turret winders

-

Cantilevered winders

- Slitter winders and rewinders

-

Specialty winders (e.g., for composite materials)

-